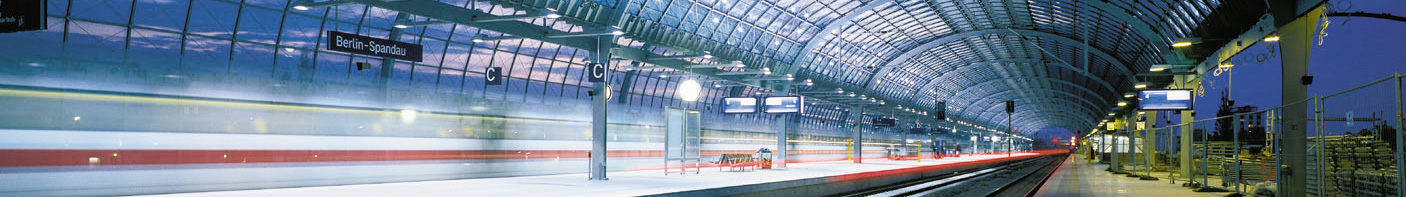

Foto:mm-fotowerbung.de

Immer kürzere Planungs- und Fertigungszeiträume erhöhen die Anforderungen an einen Stahlbauer. Der gestiegene Änderungsaufwand auch nach Fertigungsbeginn erfordert Transparenz und Flexibilität bei der eingesetzten EDV-Gesamtlösung. Hier bietet Steeloffice eine umfassende Unterstützung harmonisierter und praxiserprobter Bausteine.

Die Verknüpfung der Daten ist gewährleistet von der Erstellung der Konstruktionsdaten über die Fertigungsplanung bis hin zur Steuerung der NC-Maschinen, seien es Säge-Bohr-Kombinationen, Brennmaschinen, Stanzen oder Ausklinkanlagen.

Der Rückgriff auf den konstruktiv ermittelten Bedarf ist in den Bestellprogrammen von SteelOffice komfortabel und umfassend sichergestellt. Ebenso eine exzellente Dispositions- und Reservierungs-Logistik in der Bestandsführung, mit allen Möglichkeiten einer praxisgerechten Entnahme.

Konstruktive und terminliche Änderungen während der Bauphase werden durch automatische Warnmechanismen verfolgbar. Ein Bauzeitenplan visualisiert terminliche Zusammenhänge, das Kapazitätsauslastungsmodul unterstützt den notwendigen planerischen Vorlauf.

Permanente Kosten und Terminkontrolle sind unverzichtbar für eine erfolgreiche Projektabwicklung. Mit Steeloffice erfassen Sie die Betriebsdaten, auch online per Barcode. Die Vorgaben aus der Angebotsverarbeitung werden den tatsächlichen Kosten durch mitlaufende Kalkulation gegenübergestellt. Der Fertigungsstand der Werkstatt bleibt transparent.

Zur Dokumentation der Projekte nach den Vorgaben der DIN EN1090 verknüpft das System die verwendeten Rohmaterialien und Zeugnisse über die Rückmeldungen aus der Werkstatt.

Selbstverständlich sind Schnittstellen zu anderen kaufmännischen Programmen (zum Beispiel FIBU, Lohn & Gehalt, SAP) ebenso verfügbar wie auch die Anbindung von CAD-Systemen über die DSTV-Schnittstellen und DXF-Import oder die Möglichkeit der LV-Abrechnung nach REB, bei Bedarf auch mit Flächenberechnung nach VOB.

Unter dem Menüpunkt "SteelOffice" stellen wir Ihnen weitere und detailreiche Informationen zu unserer Softwarelösung vor. Darüber hinaus stehen Ihnen unsere Experten jederzeit für individuelle Fragen oder spezifische Problemlösungen zur Verfügung.

Mitarbeit im IT-Ausschuss des DSTV

Seit vielen Jahren arbeitet Gutsch & Exner Software aktiv im IT-Ausschuss des Deutschen Stahlbau Verbandes (DSTV) mit. Herr Gutsch hat als einer der Autoren der DSTV-Schnittstellen wesentlich Anteil daran, dass die Bedeutung des verteilten Arbeitens und der dazu notwendige Datenaustausch zwischen Planern, Fertigern und Bauherren in einer normierten Schnittstelle Niederschlag fanden.

Zum Deutschen Stahlbau-Verband